Contact Information

Lydia Slattery

Media Relations Specialist

Phone: 563-387-1417

Luther College News

Beginning with the cohort entering in fall 2024, Luther College nursing students will spend their senior year working at the Mayo Clinic in Rochester, Minnesota, rather than their junior year, to ease the transition into professional nursing after graduation.

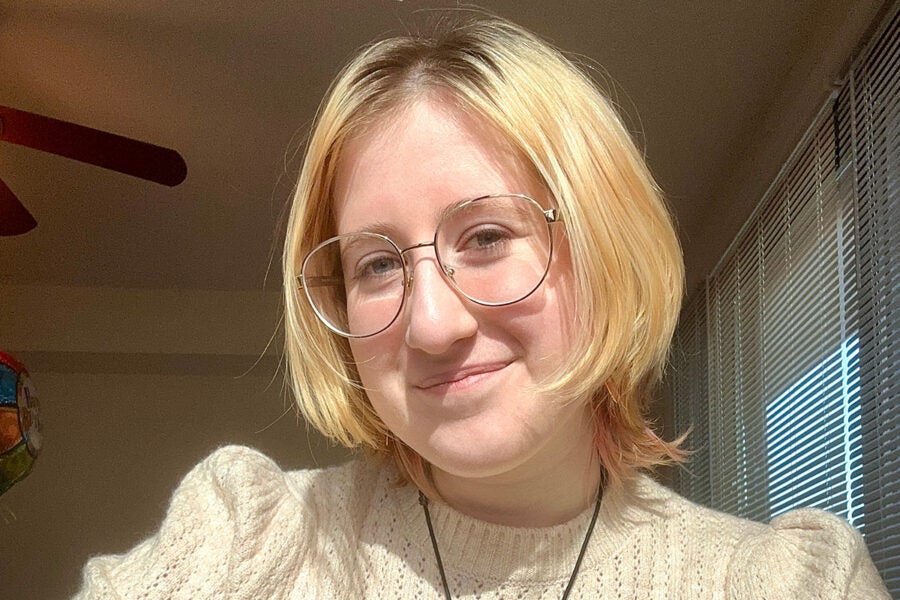

Junior Kamina Gager is one of two students interning as a processing and reference archivist in the Archives Center of the Smithsonian National Museum of American History (NMAH). Part of her job is helping to evaluate boxes of historical items, and processing and cataloging them for the museum as part of a large-scale processing project.

Small Island Big Song, a collective of renowned First Nation musicians from across the Pacific and Indian Oceans, will perform for Luther College’s Center Stage Series at 7:30 p.m Tuesday, April 23, in the Center for Faith and Life Main Hall.

Luther College will host Master Zhongxian Wu, a Chinese martial artist, calligrapher, and musician, from April 9–28. During his time on campus, he will lead workshops that are open to the Decorah community.

Luther College senior Nancy Le received the 2024 Joy Tlou Memorial Award in recognition of her contributions to campus life, encouraging a “community of joy.”

Luther College will celebrate Asian American and Pacific Islander (AAPI) heritage and contributions in April with a series of lectures, as well as performances and a fashion show put on by Luther students. The college will host a residency for a Chinese musician, calligrapher and martial artist. While May is widely recognized as the national AAPI month, Luther will celebrate in April.

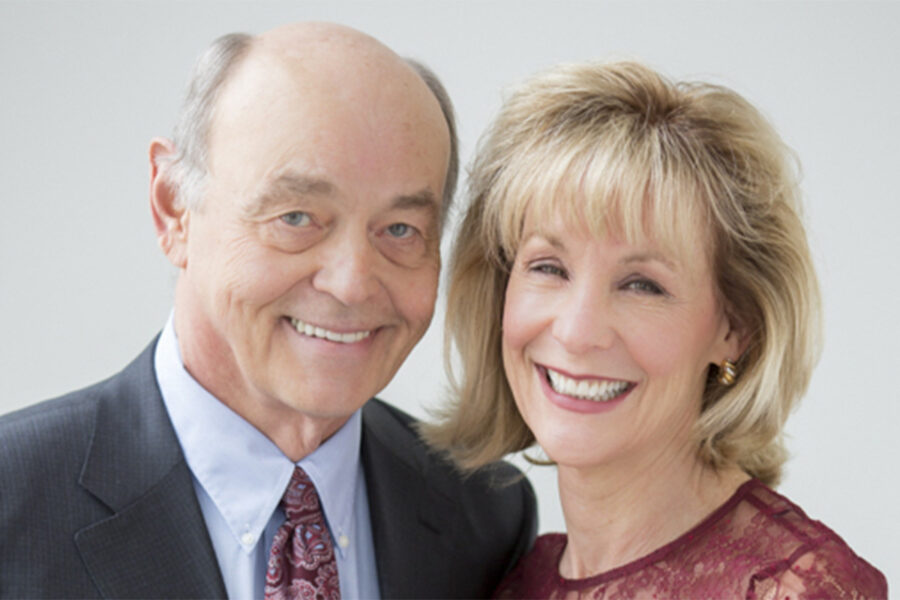

Luther College’s Center for Ethics and Public Engagement (The CEPE) will celebrate the 25th anniversary of David Lynch’s “The Straight Story,” with a free screening and discussion with one of the film’s stars in early April. The film is based on the true story of Alvin Straight of Laurens, Iowa, who rode his lawn mower tractor across the state and part of Wisconsin to reunite with his estranged brother.

Patti (Schroeder) Hetrick, class of 1984, from Minneapolis was named the vice president for finance and administration at Luther College, President Jenifer K. Ward announced this week. The native of nearby Caledonia, Minn., and graduate of Luther brings a wide range of governmental, public sector and corporate experience managing large and complex operational infrastructures.

Grace Lawrence, a senior at Luther College, is majoring in social work because she wants to help vulnerable populations. She’s spending her last semester in Washington, D.C., learning more about the social work field through an internship.

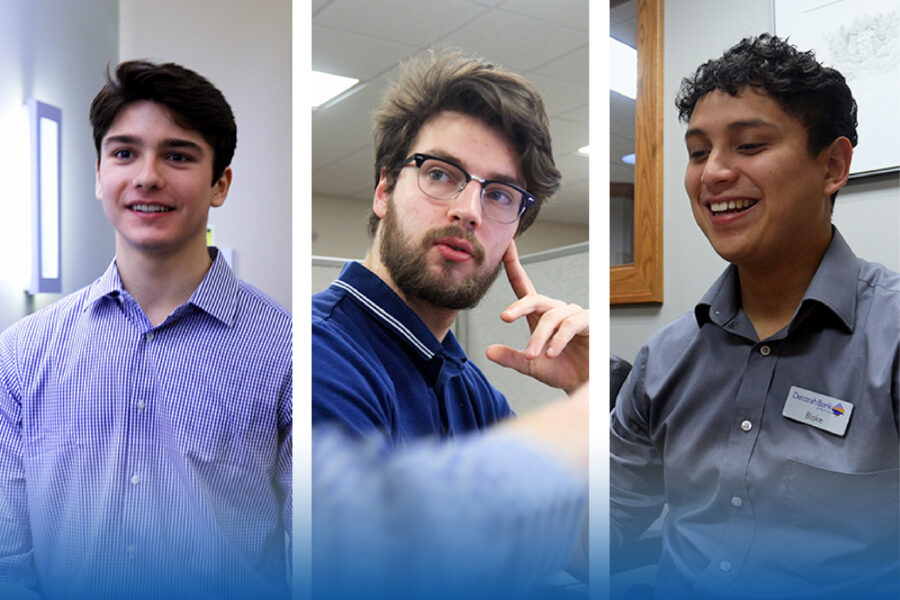

This video gives a look at how Luther students are taking advantage of experiences in the Decorah community beyond the classroom. In this video, three students – Karson Trujillo, Harrison Blum and Blake Henriquez — discuss their experiences interning with Decorah-area companies WinnMed, Deco Products and Decorah Bank and Trust.

Contact Information

Lydia Slattery

Media Relations Specialist

Phone: 563-387-1417